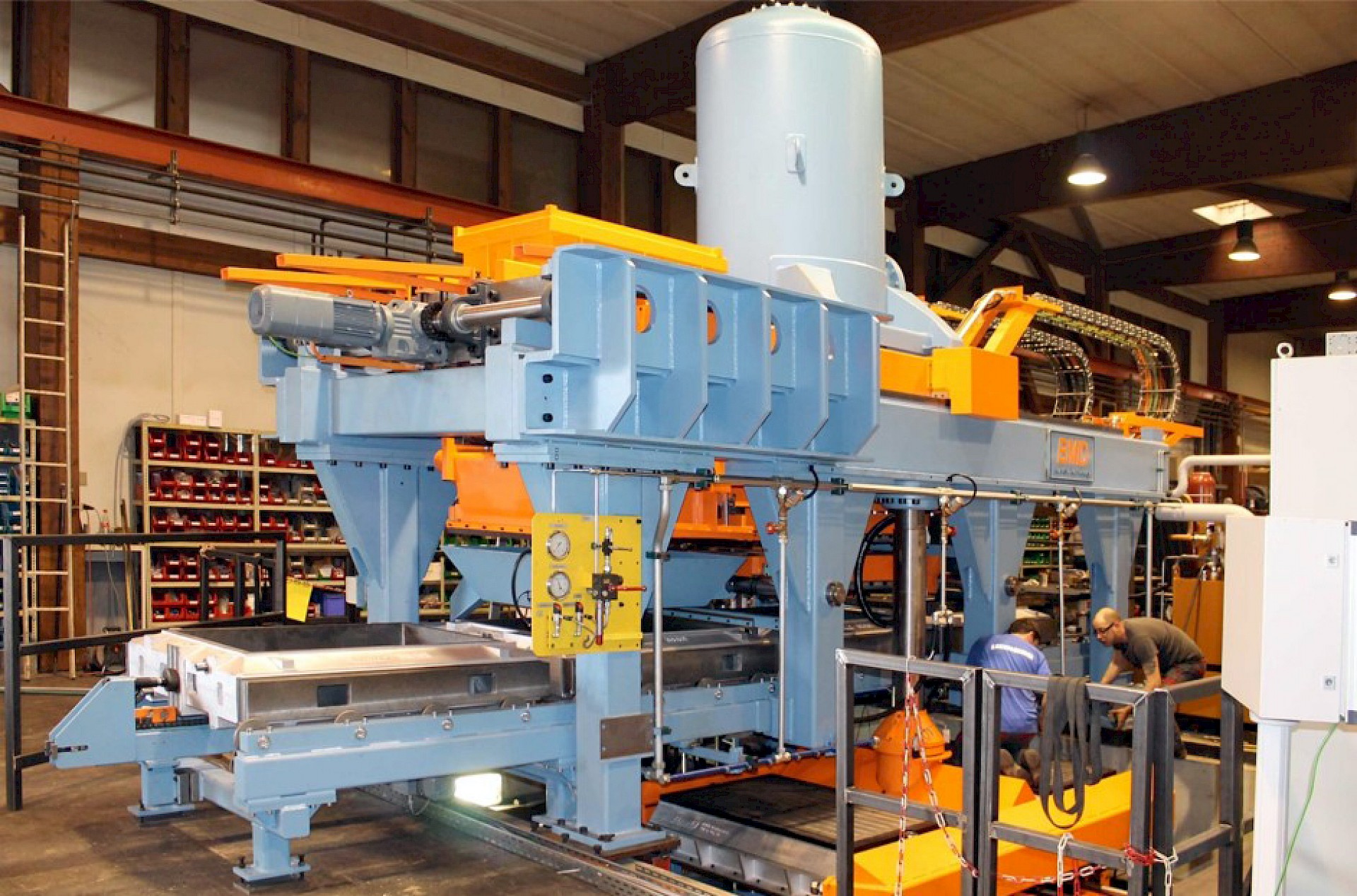

VARIO-AIR-IMPULSE Molding Machines

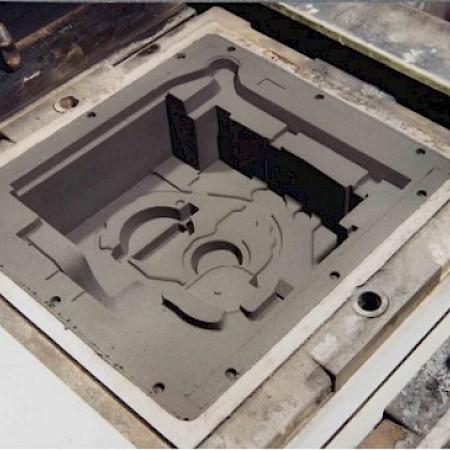

The Vario-Air-Impulse moulding machine is based on the principle of air impulse compression. Compressed air is used as the only compression medium. Compressed air is directed over a large area onto the moulding sand via an extremely fast-reacting air valve. This triggers an impulse wave in the sand, which accelerates the sand grains in the direction of the pattern bolster. The abrupt deceleration of the sand on the pattern bolster converts all of the kinetic energy into compaction energy. The process compacts the shape in a fraction of a second. The application of air and thus the hardness distribution over the mould parcel are controlled by the Vario device, whereby a uniform dimensional stability is achieved up to the edge area.

The main features of the Vario-Air-Impulse moulding machine are:

- Compression takes place in one step

- The only compression medium used is compressed air

- During compaction, there are no moving machine parts in contact with sand, so no parts can wear out

- Thanks to the vertical hardness profile in the moulding flask, even filigree models are optimally moulded and good mould degassing is ensured

- Open risers and air pipes can be moulded very easily

- Very large moulding flasks can be moulded

- Largest moulding flask format ever realized 2,600 x 1,300 x 600/600 mm

The Vario-Air-Impulse compression gives the user a competitive advantage:

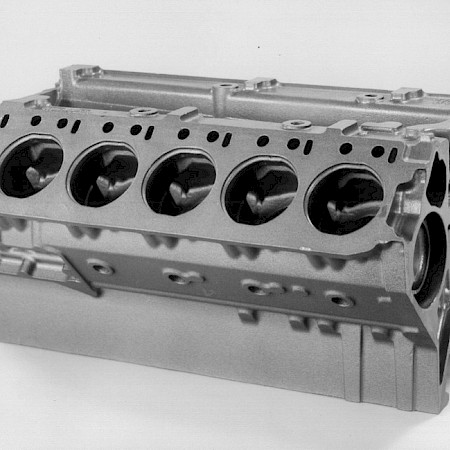

- Production of dimensionally accurate castings through precise moulding and high dimensional stability in close proximity to the model

- Production of thin-walled castings with a high degree of difficulty

- Exceptional degassing ability due to decreasing dimensional stability towards the back of the mold

- Easy adjustment of the compression intensity by regulating the pressure in the compressed air tank

- No ventilation nozzles and minimal pattern plate wear